What is a Ball Screw and Where to Find Ball Screws for Sale?

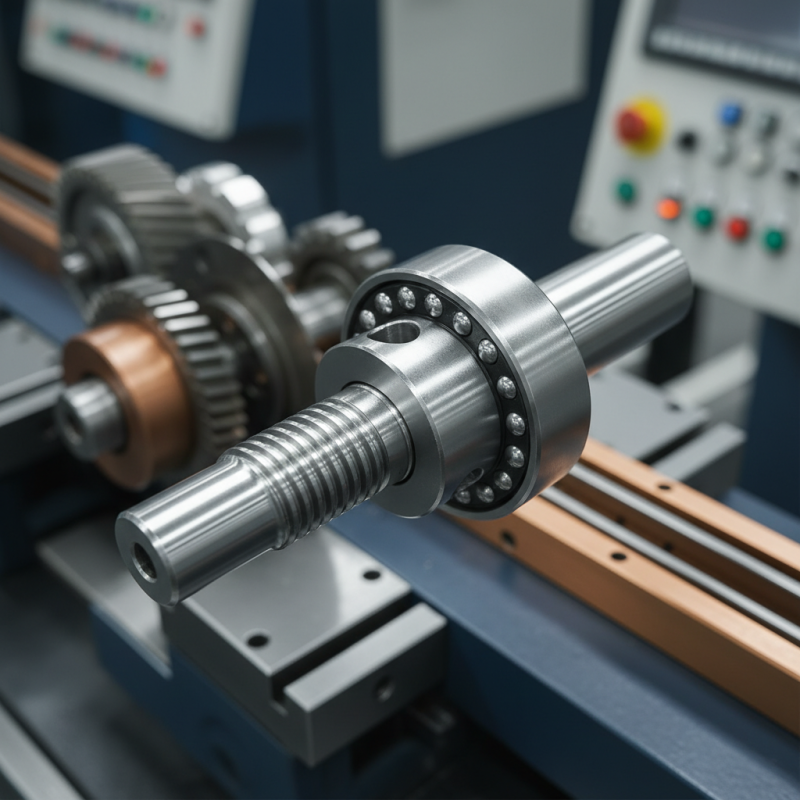

A ball screw is an essential component in many mechanical systems. It converts rotary motion into linear motion with high precision. These screws utilize ball bearings to reduce friction, leading to smoother movement and higher efficiency.

If you’re looking to improve your machinery’s performance, finding the right ball screw for sale is crucial. Online marketplaces and specialty retailers offer many options. However, the quality can vary. It’s essential to do thorough research before purchasing.

Consider your specific needs. The size, load capacity, and material of the ball screw all matter. A detailed understanding of your project will guide your choice. Finding the perfect ball screw can be challenging. But with persistence and careful consideration, you'll find the ideal component to enhance your equipment.

What is a Ball Screw and Its Function in Mechanical Systems?

A ball screw is a mechanical device widely used in precision motion control systems. It converts rotary motion into linear motion through a series of ball bearings. This design minimizes friction, leading to increased efficiency. A ball screw can achieve an impressive efficiency rate of 90% or more. This high efficiency is crucial for industrial machinery, robotics, and CNC systems.

In many applications, ball screws handle significant loads. They can support axial loads ranging from a few hundred to several tons, depending on the design. The linearity and precision of movement make them ideal for tasks requiring exact positioning. Reports indicate that the demand for ball screws in automation applications is rapidly increasing. For example, the global ball screw market is projected to reach USD 7 billion by 2027, growing at a CAGR of around 6.5% from recent years.

Finding ball screws for sale requires knowing where to look. Many manufacturers and suppliers offer a variety of types suitable for different applications. Online marketplaces have become a practical option for sourcing ball screws. However, sometimes the quality can vary significantly. It’s essential to research and ensure you are getting reliable components. Always consider the specifications you need and evaluate multiple suppliers before making a purchase.

What is a Ball Screw and Where to Find Ball Screws for Sale?

| Specification | Description | Usage Area | Average Price (USD) |

|---|---|---|---|

| Diameter: 16 mm | Compact and lightweight design | Robotics and automation | $75 |

| Diameter: 25 mm | High load capacity | CNC machinery | $120 |

| Diameter: 32 mm | Precision ball screw with excellent efficiency | Medical devices | $180 |

| Diameter: 40 mm | Heavy-duty applications | Industrial machinery | $250 |

The Construction and Components of a Ball Screw Explained

A ball screw is a mechanical device that converts rotary motion into linear motion. It consists of a screw, nut, and rolling elements, typically small balls. This design reduces friction, allowing for high efficiency in motion control. The efficiency of a ball screw can reach up to 90%, making it ideal for applications requiring precision.

The construction of a ball screw involves several key components. The screw shaft has grooves that accommodate the balls. When the screw rotates, the balls circulate within these grooves, moving the nut linearly. This setup provides smooth motion and yields higher loads without excessive wear. According to the National Precision Bearing Association, ball screws can handle loads between 500 to 3000 pounds, depending on their size and design.

The manufacturing process of ball screws is quite intricate. Precision machining is essential to ensure tight tolerances, which can be as low as 0.001 inches. Quality control measures must be in place to guarantee performance and reliability. Data from the Machine Tool Manufacturers Association indicates that improperly constructed ball screws can lead to unexpected failures and increased maintenance costs. This highlights the importance of sourcing ball screws from reputable suppliers.

Advantages of Using Ball Screws in Various Applications

Ball screws are integral in various machinery applications. They convert rotational motion into linear motion with high efficiency. According to a study from the International Journal of Engineering Research, ball screws can achieve an efficiency of over 90%. This efficiency reduces waste and optimizes energy usage, making them ideal for industrial applications.

One of the key advantages of ball screws is their durability. They are designed to handle heavy loads while maintaining accuracy. A report from the American Society of Mechanical Engineers highlights that ball screws can operate with precision tolerances of just a few microns. This capability is crucial for applications in CNC machines and robotics, where precision is paramount. However, the initial cost of ball screws can be higher than traditional lead screws. This raises questions about their use in small-scale projects.

Ball screws also provide smoother motion and less friction, leading to reduced wear over time. This aspect is particularly beneficial in high-speed applications. However, not all environments favor ball screws; contamination can lead to premature failure. It's important to weigh the potential costs and benefits before making a decision. The trade-off between performance and cost is an ongoing discussion in the engineering community.

Advantages of Using Ball Screws in Various Applications

How to Choose the Right Ball Screw for Your Project

Choosing the right ball screw for your project can be challenging. Start by determining the load requirements. Consider the maximum load your application will handle. If unsure, consult with experts or use load calculators. The accuracy of your choice affects performance.

Next, examine the screw diameter and lead. A larger diameter can handle more load, but may also add weight. The lead influences the speed and movement of the screw. A shorter lead provides precision, while a longer lead allows for faster travel. Make trade-offs based on your project's needs.

Don’t overlook the material and finish of the ball screw. Different materials offer various benefits like strength and corrosion resistance. Reflect on the operating environment. Will it be exposed to moisture or dust? Selecting the right material can prevent premature wear. It’s crucial to balance these factors carefully for optimal results.

Where to Find Ball Screws for Sale: Suppliers and Online Options

When searching for ball screws, a variety of suppliers offer valuable options. Local manufacturers and larger distributors frequently maintain inventory. According to industry reports, the global market for ball screws is projected to reach over $6 billion by 2025. This growth reflects a rising demand in automation and precision engineering.

Online platforms provide convenient alternatives. Websites dedicated to industrial components often list multiple ball screw variations. Users can filter options by specifications, such as diameter or length. Market research indicates that e-commerce in industrial parts has surged by 15% annually. However, purchasing online can be daunting. Customers must verify compatibility and specifications, which can lead to confusion.

In-person visits to trade shows may yield ideal results. Engaging directly with manufacturers gives insight into quality. However, not all suppliers maintain high standards. Some may prioritize cost over quality, risking long-term reliability. Relying too heavily on reviews without personal inspection can be misleading. Take time to evaluate options thoroughly for better outcomes.